Adopt a Lean Approach to Viscosity Control: Automate Monitoring and Controlling Viscosity In Your Process

We’re in an age of industrial transformation. Industry 4.0, automation, IIoT, Smart Manufacturing, and an ever-increasing number of new technologies continue to disrupt old methods.

Viscosity control is no different.

If you’re practicing older methods, adapting now will help you stay competitive and improve your processes. We can help.

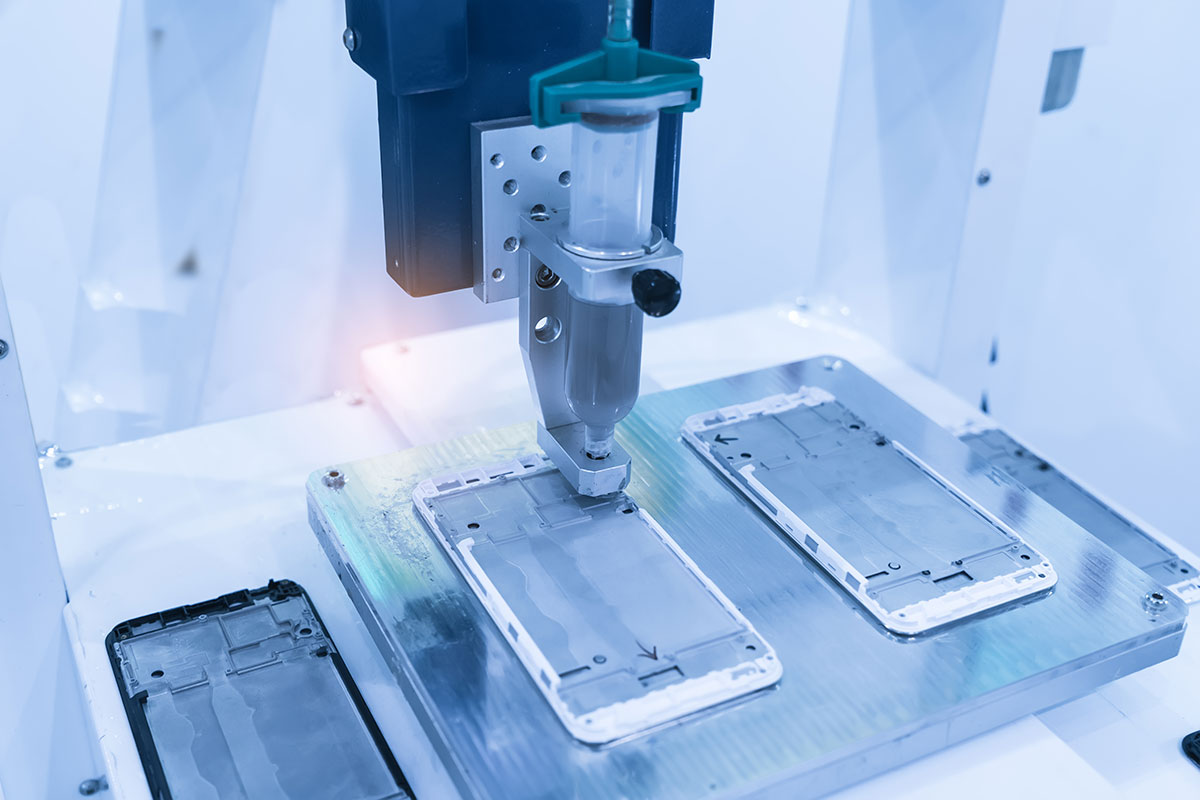

Taking manual measurements (think Zahn cup) and manually adding solvent every hour, shift, and day is costing you money. People operate at different baselines; Human abilities differ by the individual, mistakes/oversight happen, there’s only so much time. This is an inefficient process. An automated system can measure in real time, at any time, all the time. Our control system automatically adds solvent in the precise amount exactly when it’s necessary.

The result: the most effective viscosity control system available that reduces waste, saves time, eliminates human error, and leaves your people available to perform more important tasks.

Let us show you how.

How Continuous Monitoring and Automated Adjustments Work

Variables cause viscosity to fluctuate all the time. If, for example, a person at your plant is dipping a cup once an hour to measure viscosity, you’re just getting a one-minute snapshot of that particular hour and manual adjustments in response to that one minute. But viscosity will continue to fluctuate until the next manual checks and adjustments. The viscosity variation cycle repeats.

This inefficient, costly method was once necessary. But not anymore.

When you automate your process with permanent monitoring, you can monitor and adjust your viscosity in real time to maintain constant viscosity. That means precise results, shift after shift, day after day.

It’s time to maximize your process efficiency.

Viscosity Control Tools and Technology

Saint Clair Systems engineers have created inline viscometers, sensors, and intuitive control systems that are easy to use and perform well consistently. It’s time to consider Zahn cups a thing of the past.

Vibrational Viscosity Sensor

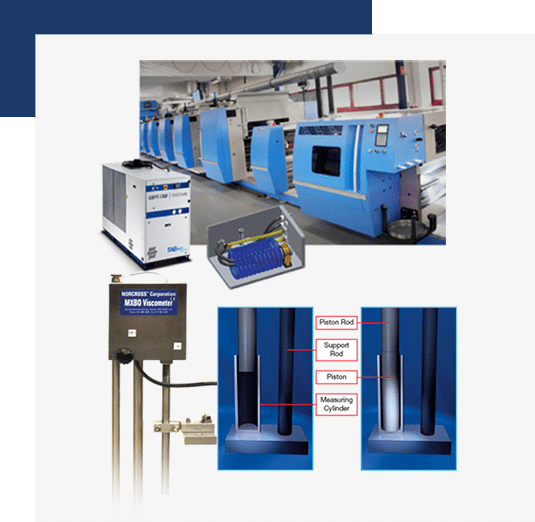

Falling Piston Viscosity Sensor

VC-4500 and VC-4600 Series Viscosity Controller

The VC-4500 and VC-4600 are PLC-based Process Control Systems with a Touch Screen GUI Interface that provide a unique set of control options designed specifically for fluid dispensing processes. Each combines four basic functions: