Controlling Temperature and Viscosity in Industrial Finishes is Nothing New

So what makes us different?

We aren’t different because we control temperature. We’re different because of where we control it. That’s the game-changer. And the results speak for themselves.

Temperature is a constant variable in your industrial finishing systems.

As temperature changes, viscosity varies. And these variations create inconsistencies that are negatively impacting your business.

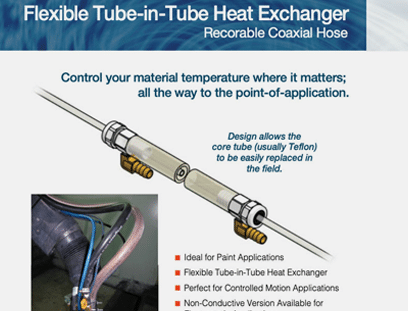

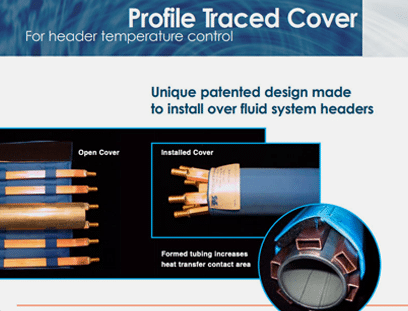

Where you control temperature matters. If you’re not controlling temperature at the point where the material is dispensed, you’re leaving the material susceptible to process variables like ambient temperature and friction. Completely avoidable problems unfold when variations like these are part of your finishing process.

The solution we provide is high-precision temperature control at the point of application. The temperature of your industrial finish material is fixed at +/- 1°F at the most critical moment of its dispense journey. Despite temperature fluctuations in and around your process, viscosity remains constant and consistent part-after-part, shift-after-shift, day-after-day..

No one else in our industry does that.

How Does Our Temperature Control Technology Benefit Your Industrial Finishes & Systems?

Unparalleled consistency in your finishing application creates a more uniform finish that results in higher-quality finished products, increased efficiency, and improved profitability.

Material, labor, energy and environmental wastes are drastically reduced (and in some cases, eliminated entirely!).

Save money on waste-associated costs.

Constant viscosity minimizes defects and rework and increases first pass yield.

Consistent quality, reduced downtime, faster processing times, optimized material use, and improved energy use.

Consistent coating thickness, uniform appearance, reduced defects, improved adhesion, and increased durability.

Promoting efficiency, improving quality, reducing costs, using disruptive technology for the competitive advantage, and increasing your first pass yield all contribute greater profitability.

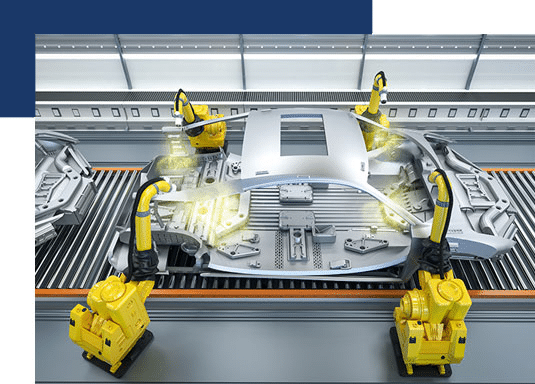

Becomes an integral, incredibly easy-to-maintain part of your process. It’s a “set and forget” operation ready to fit seamlessly into your automated finishing systems.

How Controlling Temperature at the Point of Application Works

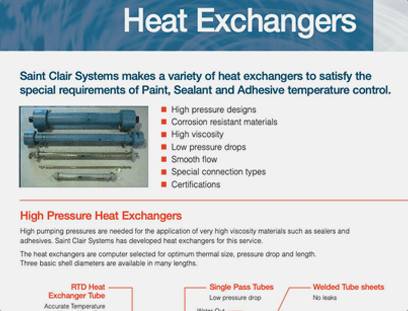

Trying to control temperature from its origin to the point-of-application can have a dramatic impact on material costs. Learn how you can improve quality and save money with Saint Clair Systems.